wood cutting board set manufacturer

A wood cutting board set manufacturer represents a specialized enterprise dedicated to crafting premium kitchen essentials through advanced production methods and superior material selection. These manufacturers combine traditional woodworking expertise with modern manufacturing technologies to create durable, food-safe cutting surfaces. Their production facilities typically feature state-of-the-art CNC machinery, precision cutting equipment, and specialized finishing stations that ensure consistent quality across all products. The manufacturing process encompasses careful wood selection, moisture content monitoring, precise dimensioning, and multiple stages of sanding and finishing. These facilities often maintain strict quality control measures, including material testing, durability assessments, and food safety certifications. The manufacturer's capabilities extend beyond basic cutting boards to include specialized products such as end-grain boards, carving stations, and serving platters. Their operations typically integrate sustainable practices, from responsible wood sourcing to eco-friendly finishing treatments. Many manufacturers also offer customization options, allowing clients to specify dimensions, wood types, and design elements to meet specific requirements.

FSC-certified Bamboo

FSC-certified Bamboo

Custom Packaging

Custom Packaging

Bulk Discounts

Bulk Discounts

Meet Our Artisans

Meet Our Artisans

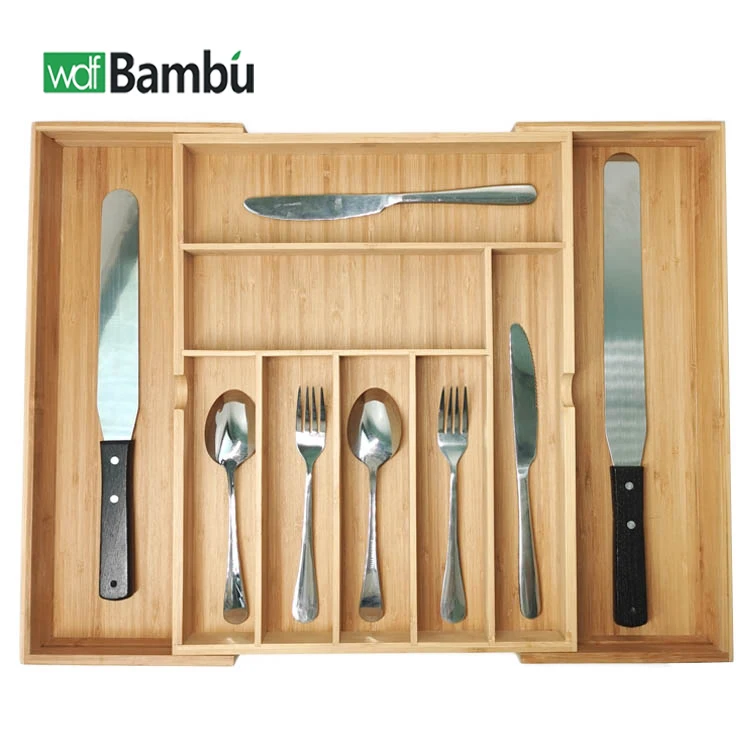

Modernized for Your Home

Modernized for Your Home

Our Story Begins in

Our Story Begins in

Home

Home