Introduction

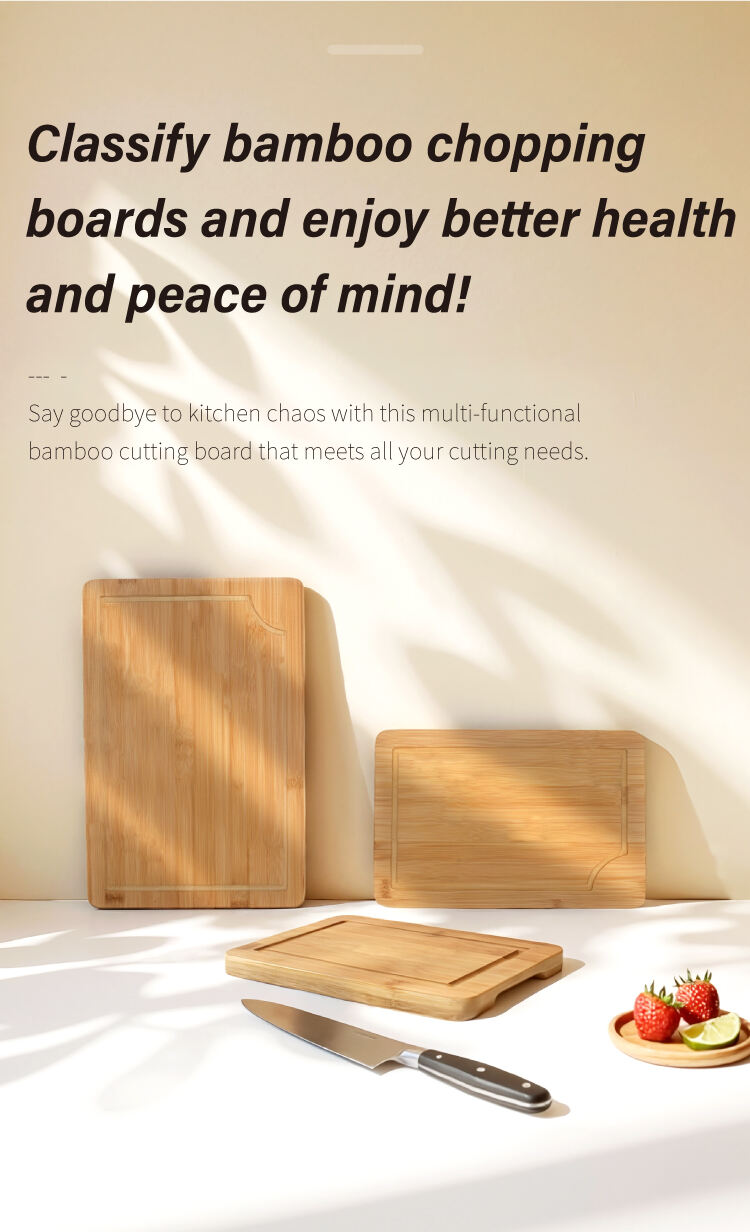

Professional kitchens and culinary environments demand cutting boards that combine durability, functionality, and hygiene standards. The 3-Piece Large Bamboo Cutting Boards Set for Kitchen, Heavy Duty Cutting Board with Juice Groove, Bamboo Chopping Board Set represents an exceptional solution for commercial food preparation operations, restaurants, and professional cooking facilities worldwide. This comprehensive bamboo cutting board collection delivers the perfect balance of sustainability, performance, and practical design elements that modern food service establishments require for their daily operations.

Bamboo has emerged as the preferred material for professional cutting surfaces due to its natural antimicrobial properties, exceptional durability, and environmental sustainability. This thoughtfully designed cutting board set addresses the diverse needs of commercial kitchens while maintaining the highest standards of food safety and operational efficiency. Each board in this collection features specialized design elements that enhance food preparation workflows and contribute to maintaining optimal hygiene standards in professional culinary environments.

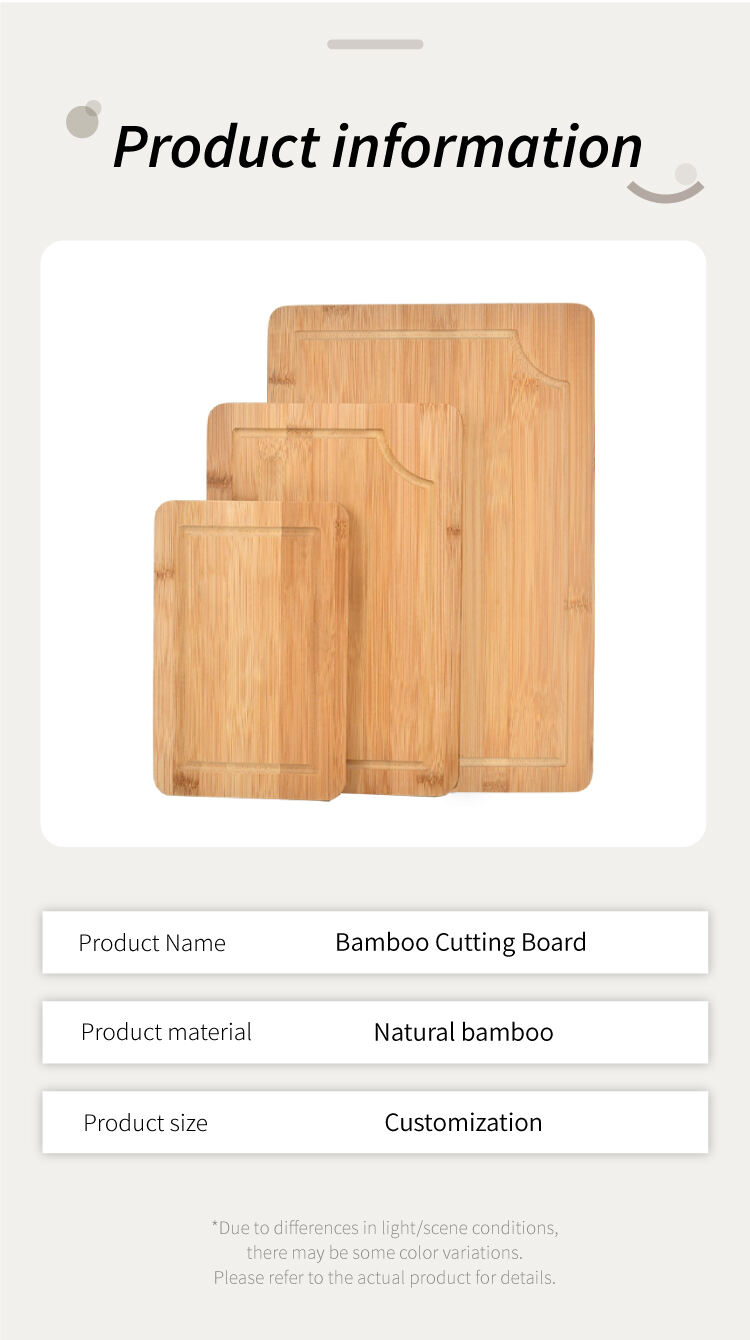

Product Overview

This premium bamboo cutting board collection encompasses multiple board sizes within a single set, providing comprehensive cutting surface solutions for varied food preparation tasks. The heavy-duty construction ensures long-lasting performance under demanding commercial kitchen conditions, while the integrated juice grooves capture liquids effectively during meat preparation and other moisture-intensive cutting operations. The natural bamboo composition offers superior resistance to bacterial growth compared to traditional plastic cutting surfaces, making it an ideal choice for food safety-conscious establishments.

The 3-Piece Large Bamboo Cutting Boards Set for Kitchen, Heavy Duty Cutting Board with Juice Groove, Bamboo Chopping Board Set features carefully engineered surface textures that provide optimal cutting performance while preserving knife blade sharpness over extended use periods. The boards maintain dimensional stability under varying temperature and humidity conditions, ensuring consistent performance across different kitchen environments and seasonal variations.

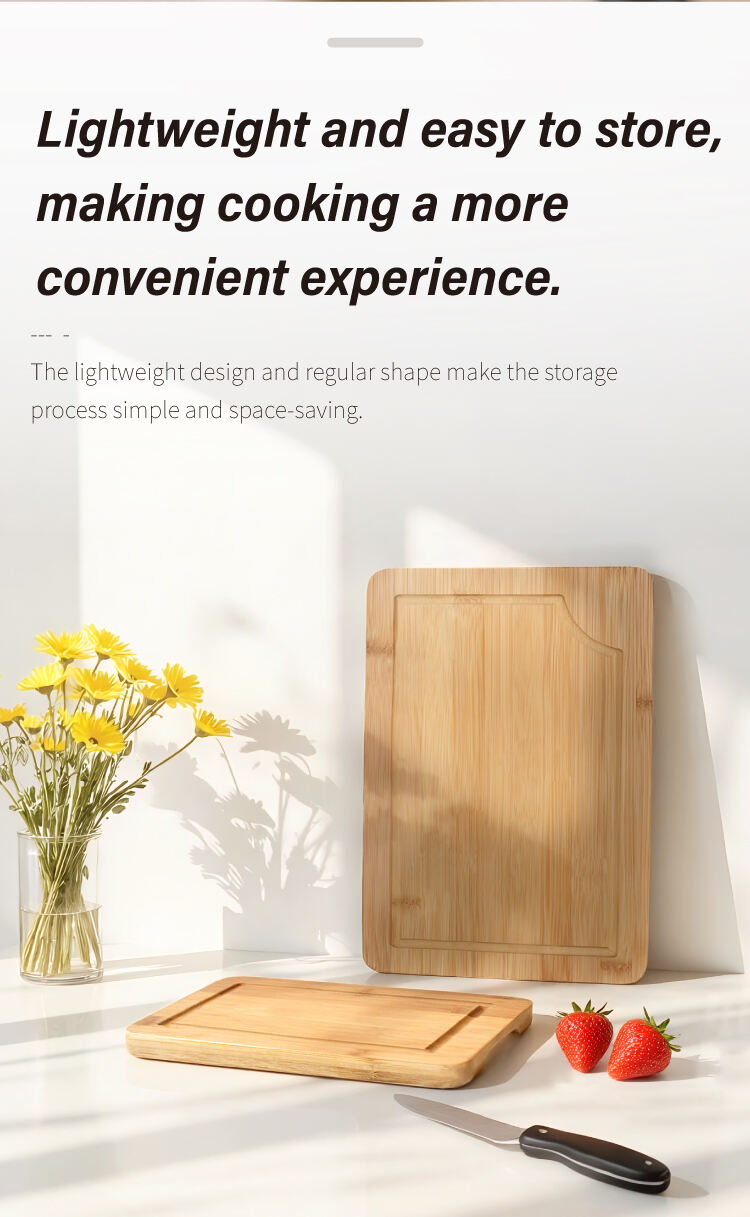

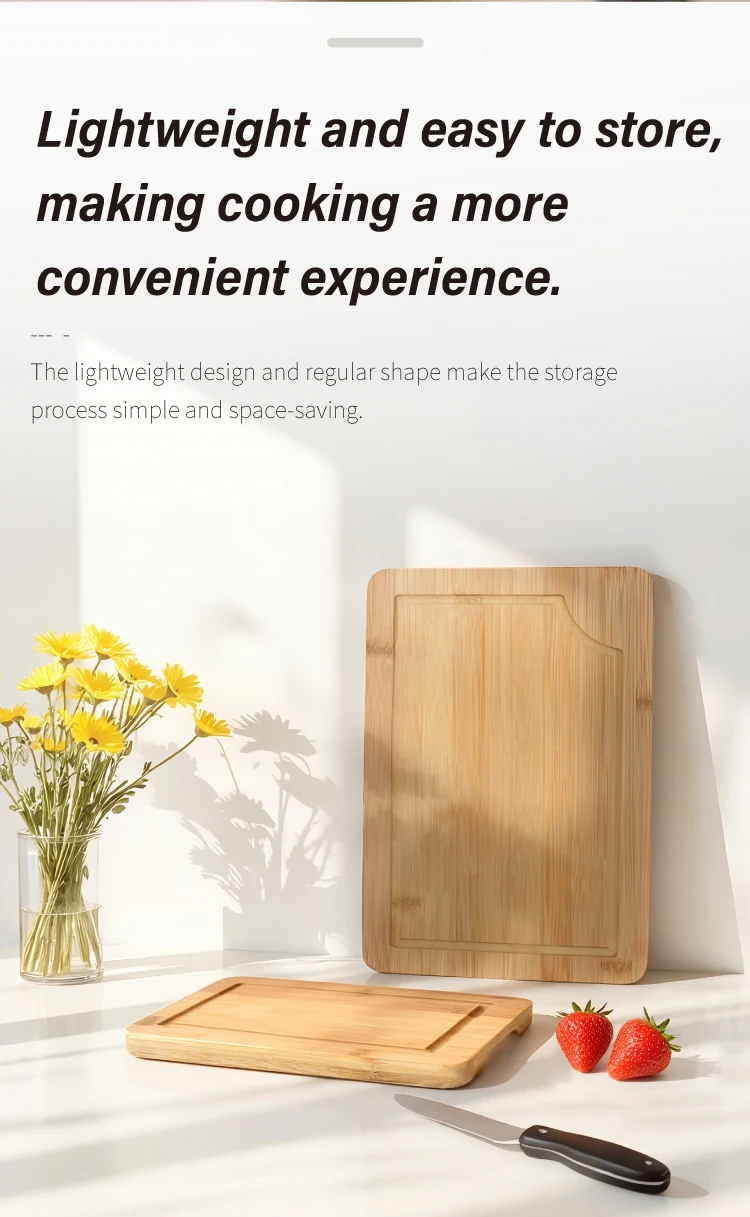

Each cutting board incorporates ergonomic design principles that facilitate comfortable handling and efficient food preparation workflows. The substantial thickness provides stability during intensive chopping operations while maintaining manageable weight characteristics for practical daily use. The smooth, non-porous bamboo surface resists staining and odor absorption, ensuring that each board maintains its professional appearance throughout its extended service life.

Features & Benefits

Advanced Bamboo Construction Technology

The cutting boards utilize premium-grade bamboo construction that delivers exceptional durability and performance characteristics. Bamboo's natural density provides superior resistance to cutting marks and surface damage while maintaining gentle interaction with knife edges. This advanced material composition ensures that the boards withstand intensive daily use in high-volume food preparation environments without compromising their structural integrity or surface quality.

The heavy-duty construction methodology employed in manufacturing these boards creates cutting surfaces that resist warping, cracking, and splitting under demanding operational conditions. The bamboo fibers are oriented and compressed to maximize strength while maintaining the material's natural antimicrobial properties that contribute significantly to food safety standards in commercial kitchen applications.

Integrated Juice Groove System

The strategically positioned juice grooves around the perimeter of each board provide effective liquid containment during food preparation activities. These professionally designed channels capture meat juices, vegetable liquids, and other moisture while preventing spillage onto work surfaces and floors. The groove dimensions are optimized to contain adequate liquid volume while remaining easy to clean and maintain according to commercial kitchen hygiene protocols.

This integrated containment system enhances workplace safety by reducing slip hazards associated with liquid spillage while maintaining cleaner work environments throughout busy service periods. The smooth groove surfaces facilitate thorough cleaning and sanitization, ensuring that the boards meet stringent food safety requirements across various culinary applications and preparation styles.

Multi-Size Versatility

The comprehensive set design provides cutting surface options suitable for diverse food preparation requirements within a single collection. Different board sizes accommodate various ingredient types and cutting techniques, from delicate herb preparation to substantial protein portioning tasks. This versatility eliminates the need for multiple separate cutting board purchases while ensuring optimal cutting surface availability for every kitchen operation.

The varied sizes within the Heavy Duty Cutting Board with Juice Groove, Bamboo Chopping Board Set enable efficient workflow organization and cross-contamination prevention through dedicated board usage for specific ingredient categories. Professional kitchens can implement color-coding systems or designated usage protocols to maintain food safety standards while maximizing operational efficiency across multiple preparation stations.

Applications & Use Cases

Commercial restaurant operations benefit significantly from the durability and performance characteristics of this professional bamboo cutting board collection. High-volume establishments require cutting surfaces that maintain their integrity throughout intensive daily service while supporting diverse menu preparation requirements. The boards excel in applications ranging from vegetable preparation and meat portioning to bread cutting and garnish creation, providing consistent performance across all culinary disciplines.

Catering operations and mobile food service providers find exceptional value in the lightweight yet durable construction of these bamboo boards. The natural antimicrobial properties support food safety requirements during transport and off-site preparation activities, while the robust construction withstands the challenging conditions associated with mobile kitchen environments. The juice groove system proves particularly valuable during outdoor events and temporary kitchen setups where spill containment is critical.

Professional culinary schools and training institutions utilize these cutting board sets to provide students with industry-standard equipment that mirrors commercial kitchen conditions. The educational value extends beyond basic cutting techniques to include proper sanitation protocols, cross-contamination prevention methods, and sustainable kitchen practices. The boards' longevity ensures consistent training experiences across multiple student cohorts while maintaining cost-effectiveness for educational budgets.

Food processing facilities and commissary kitchens incorporate these bamboo cutting boards into their specialized preparation workflows. The boards' resistance to bacterial growth and ease of sanitization support compliance with commercial food safety regulations while providing reliable cutting surfaces for large-scale ingredient preparation. The multiple size options facilitate efficient space utilization and workflow optimization in industrial kitchen environments.

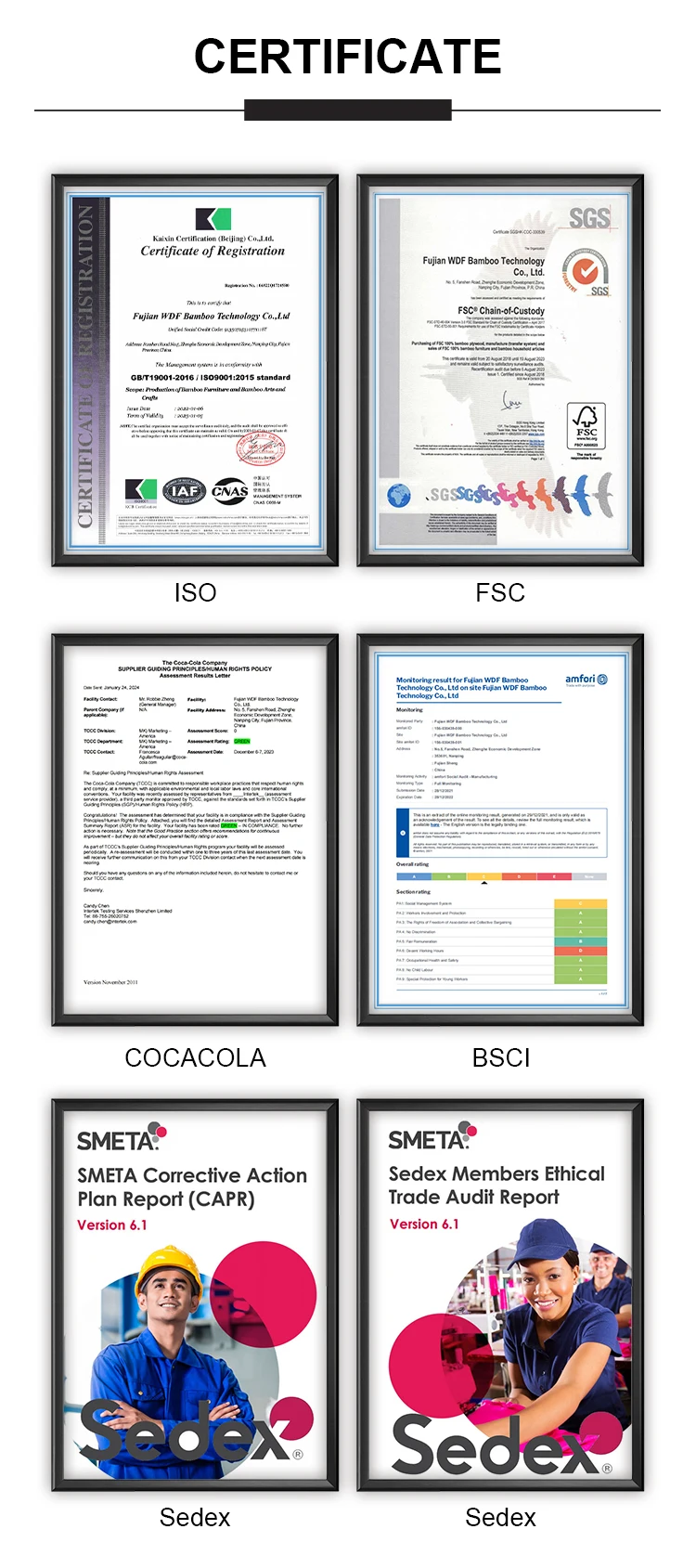

Quality Control & Compliance

Rigorous quality assurance protocols ensure that every 3-Piece Large Bamboo Cutting Boards Set for Kitchen meets international food safety standards and commercial kitchen requirements. The manufacturing process incorporates multiple inspection stages that verify bamboo quality, construction integrity, and surface finish consistency. These comprehensive quality control measures guarantee that each cutting board delivers reliable performance and maintains food safety compliance throughout its operational lifespan.

The bamboo sourcing program adheres to sustainable forestry practices while ensuring material quality and consistency across production batches. Advanced processing techniques preserve the bamboo's natural antimicrobial properties while enhancing its durability and performance characteristics. The resulting cutting boards meet or exceed industry standards for commercial food preparation surfaces while supporting environmental sustainability goals.

Food safety compliance extends throughout the entire production process, from raw material selection through final packaging procedures. The boards undergo thorough cleaning and sanitization protocols before packaging, ensuring they arrive ready for immediate commercial kitchen integration. Documentation and traceability systems support regulatory compliance requirements and enable comprehensive quality monitoring across international distribution channels.

Regular testing protocols verify the boards' resistance to bacterial growth, surface integrity under stress conditions, and dimensional stability across varying environmental factors. These ongoing quality assessments ensure consistent product performance and reliability while identifying opportunities for continuous improvement in manufacturing processes and material specifications.

Customization & Branding Options

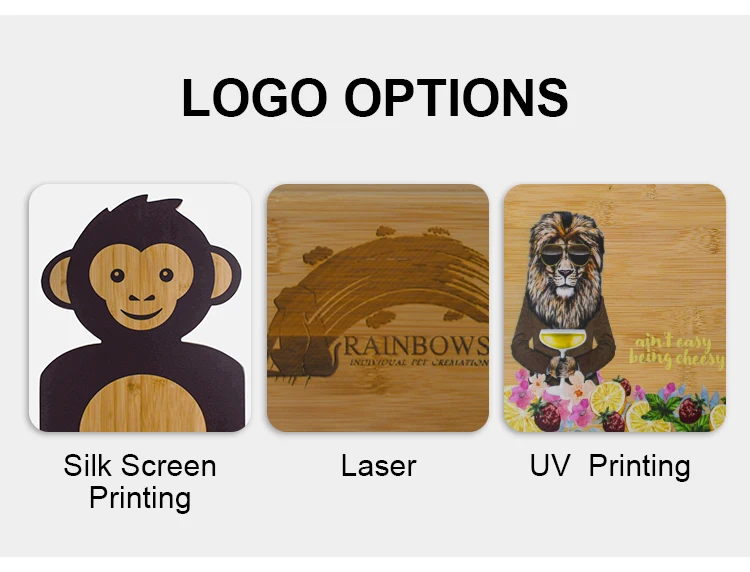

Comprehensive customization services enable food service businesses to incorporate their branding elements into these professional cutting board sets. Custom engraving options allow restaurants, catering companies, and culinary schools to add logos, establishment names, or specialized markings that enhance brand recognition and professional presentation. The bamboo surface accepts various engraving techniques while maintaining structural integrity and food safety compliance.

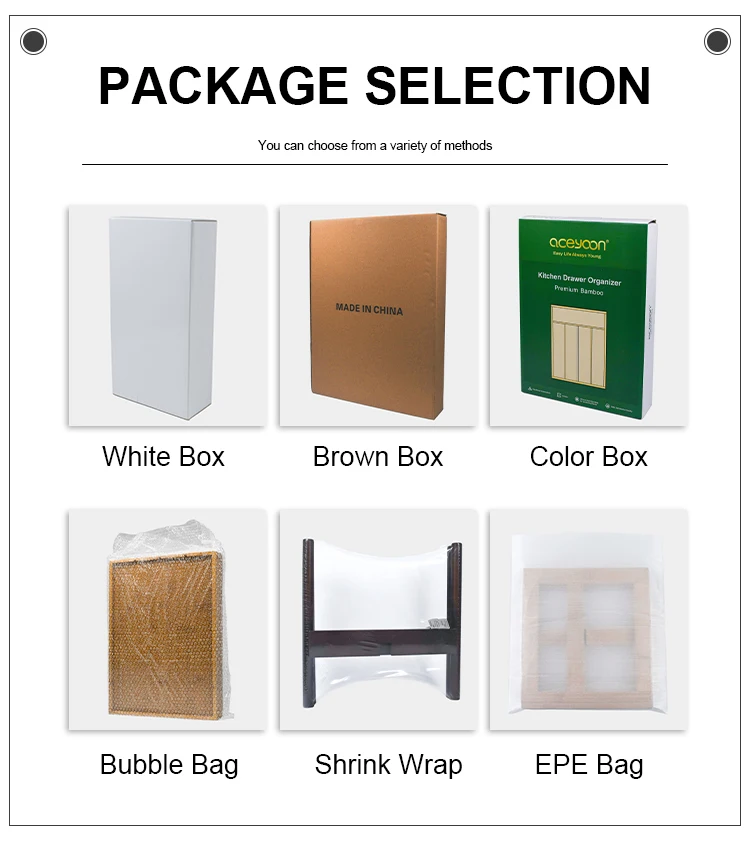

Private labeling opportunities support distributors and retailers seeking to offer branded kitchen equipment solutions to their commercial customers. Custom packaging options complement the branding initiatives while maintaining product protection and presentation standards throughout distribution channels. These customization services extend to specialized size configurations that address unique operational requirements in specific market segments.

Color-coding systems can be implemented through natural bamboo staining techniques that maintain food safety standards while enabling visual identification for cross-contamination prevention protocols. These customization options prove particularly valuable in large commercial kitchens where multiple cutting boards are used simultaneously across different preparation stations and ingredient categories.

Specialized surface treatments and finishing options accommodate specific operational requirements while preserving the bamboo's natural performance characteristics. Custom grip enhancements, specialized edge treatments, and modified groove configurations represent additional customization possibilities that address unique workflow requirements in specialized culinary applications and food processing operations.

Packaging & Logistics Support

Professional packaging systems protect the cutting board sets throughout international shipping and distribution processes while maintaining presentation standards for retail and commercial customers. The packaging design incorporates protective elements that prevent damage during handling while facilitating efficient warehouse storage and inventory management across global distribution networks.

Sustainable packaging materials align with the environmental benefits of bamboo cutting boards while providing adequate protection for international transportation requirements. The packaging systems accommodate various shipping methods and distribution channels while maintaining cost-effectiveness for bulk orders and individual shipments. Clear product identification and specification information support efficient inventory management and customer satisfaction.

Logistics partnerships facilitate reliable delivery schedules and competitive shipping rates for customers worldwide. The packaging configurations optimize container utilization and reduce transportation costs while maintaining product protection standards. These logistics capabilities support both large-scale commercial orders and smaller specialty purchases across diverse market segments and geographic regions.

Documentation and certification packages accompany each shipment to support customs clearance, regulatory compliance, and customer quality assurance requirements. The comprehensive documentation includes product specifications, quality certifications, and care instructions that facilitate smooth integration into commercial kitchen operations and regulatory compliance protocols.

Why Choose Us

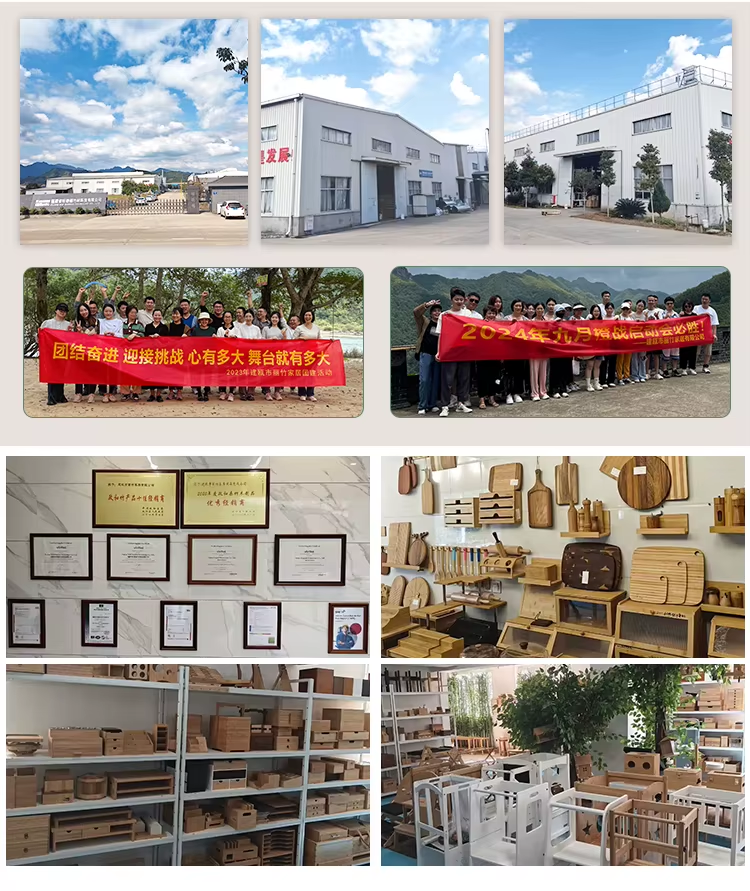

Our company brings extensive experience in manufacturing premium bamboo kitchen products for international markets, establishing strong partnerships with commercial food service operations, distributors, and culinary professionals worldwide. This long-standing expertise enables us to understand the evolving needs of modern commercial kitchens while maintaining unwavering commitment to quality, sustainability, and customer satisfaction across diverse market segments.

The comprehensive approach to product development incorporates feedback from professional chefs, food safety experts, and commercial kitchen operators to ensure that every Bamboo Chopping Board Set delivers optimal performance in real-world applications. This collaborative development process results in cutting boards that address practical operational challenges while exceeding industry standards for durability, hygiene, and functionality.

Global supply chain capabilities ensure consistent product availability and reliable delivery schedules for customers across multiple continents. The established distribution network includes partnerships with specialized kitchen equipment suppliers, food service distributors, and culinary equipment retailers who understand the unique requirements of commercial kitchen operations and professional food preparation environments.

Continuous innovation in bamboo processing techniques and cutting board design elements maintains our competitive position while advancing sustainability goals and performance standards. The research and development initiatives focus on emerging market needs, technological advances, and environmental considerations that shape the future of commercial kitchen equipment and sustainable food service operations.

Conclusion

The 3-Piece Large Bamboo Cutting Boards Set for Kitchen, Heavy Duty Cutting Board with Juice Groove, Bamboo Chopping Board Set represents the ideal solution for professional food service establishments seeking sustainable, durable, and high-performance cutting surfaces. The combination of premium bamboo construction, integrated juice groove systems, and comprehensive size options addresses the diverse requirements of modern commercial kitchens while supporting environmental sustainability goals and food safety compliance standards. This exceptional cutting board collection delivers long-term value through superior durability, natural antimicrobial properties, and versatile applications across multiple culinary disciplines and food service environments, making it an essential investment for any professional kitchen operation focused on quality, efficiency, and sustainability.

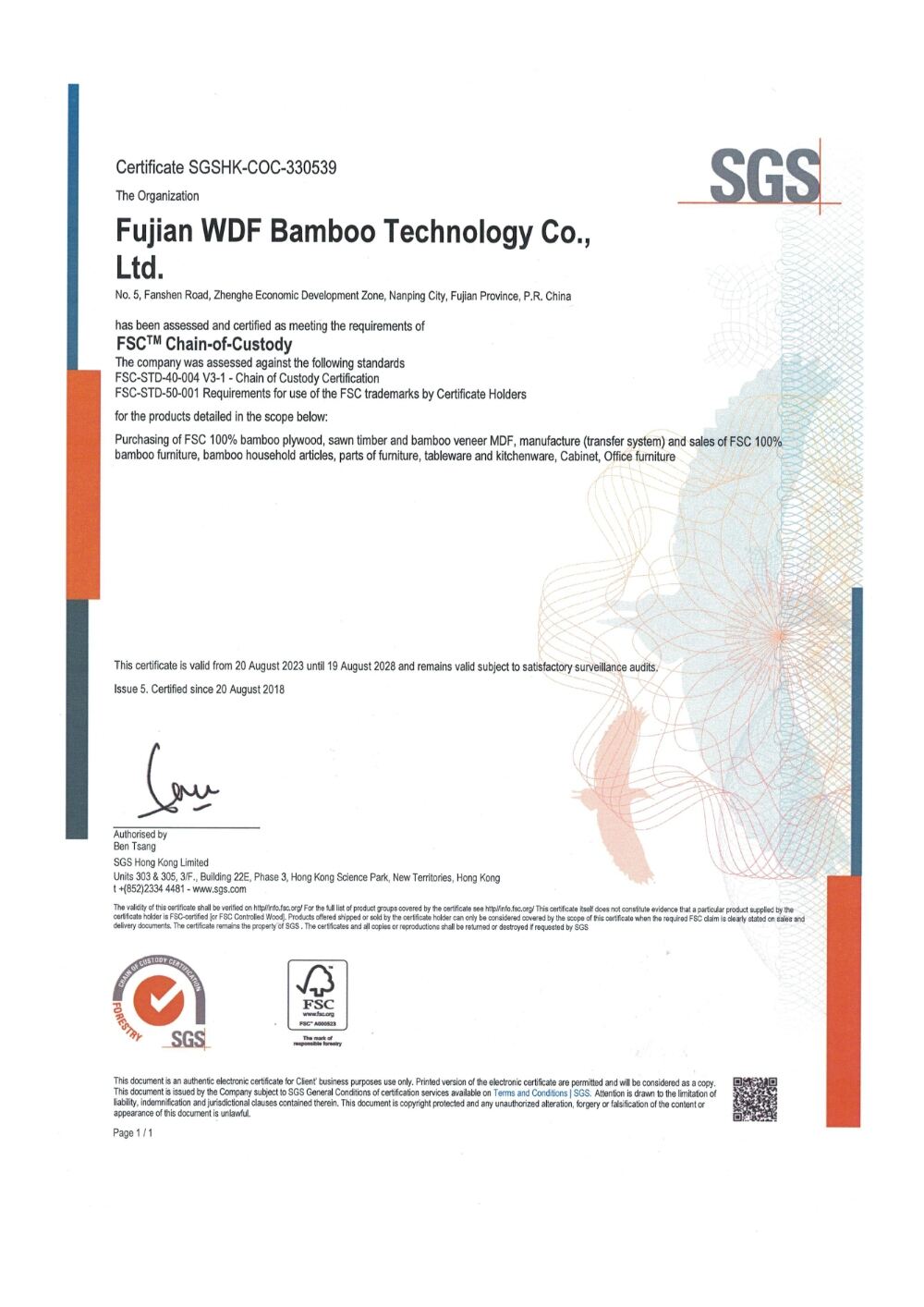

FSC-certified Bamboo

FSC-certified Bamboo

Custom Packaging

Custom Packaging

Bulk Discounts

Bulk Discounts

Meet Our Artisans

Meet Our Artisans

Modernized for Your Home

Modernized for Your Home

Our Story Begins in

Our Story Begins in

Home

Home